Blog

Latest articles from Sourcemap

categories

All

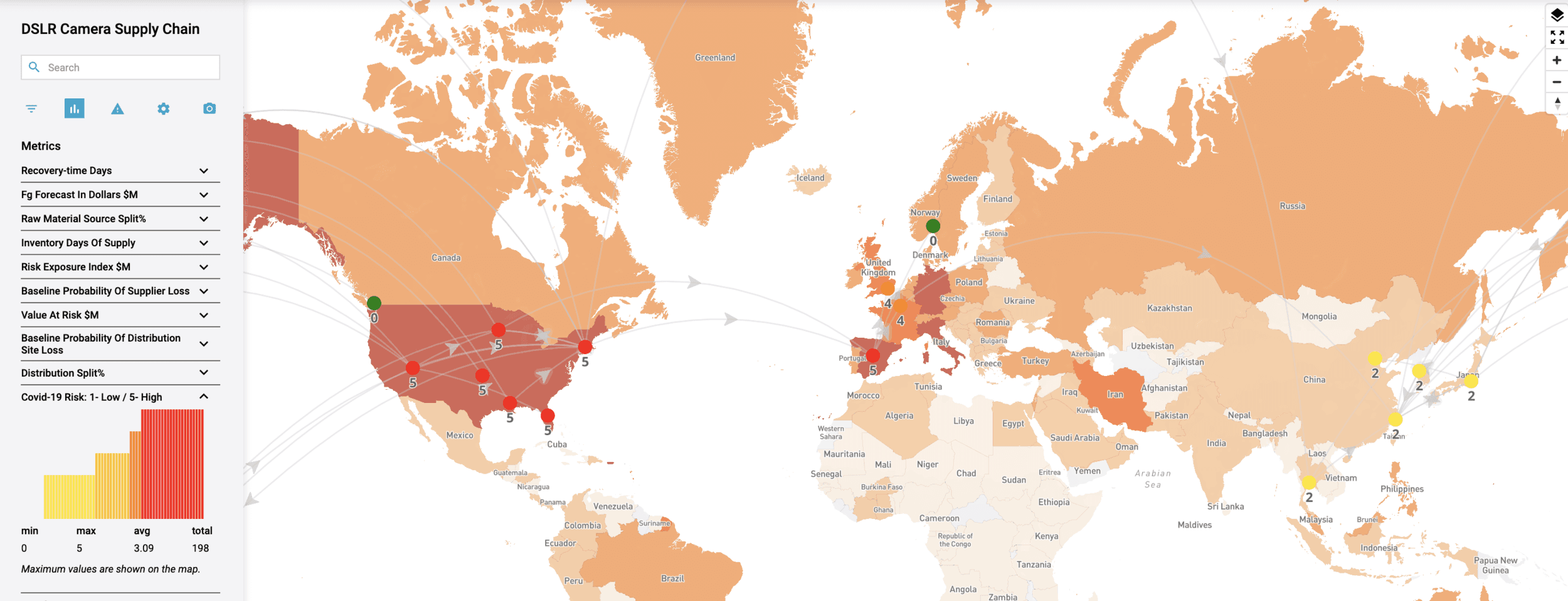

Business Resilience

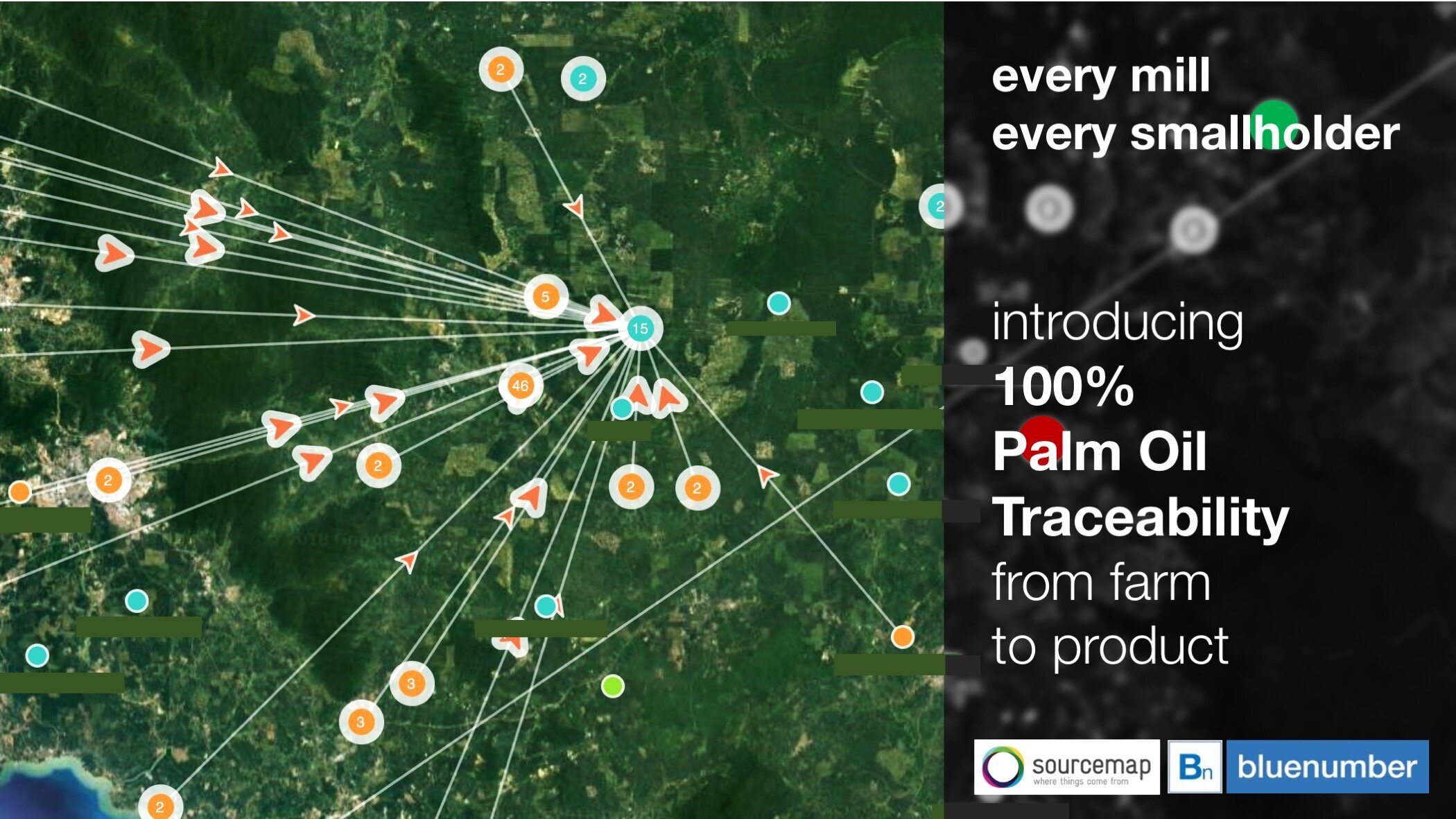

Deforestation

Environmental Responsibility

Industry Trend

Labor and Human Rights

Policy

Sourcemap

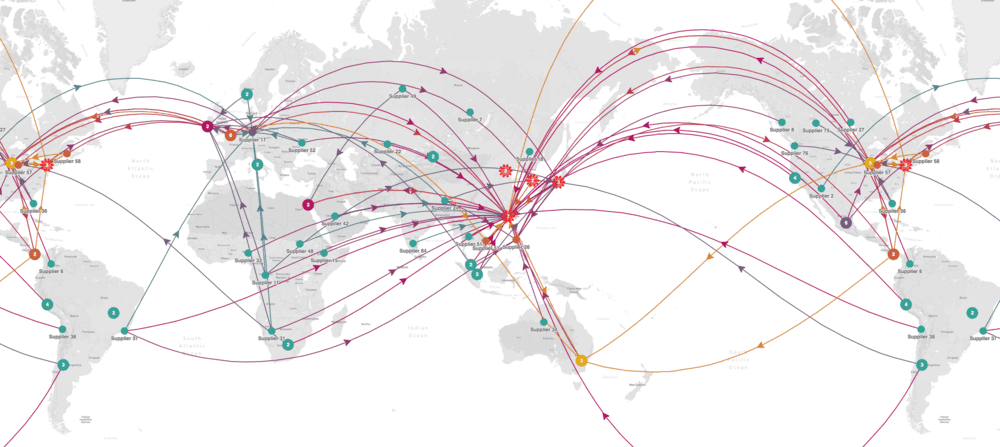

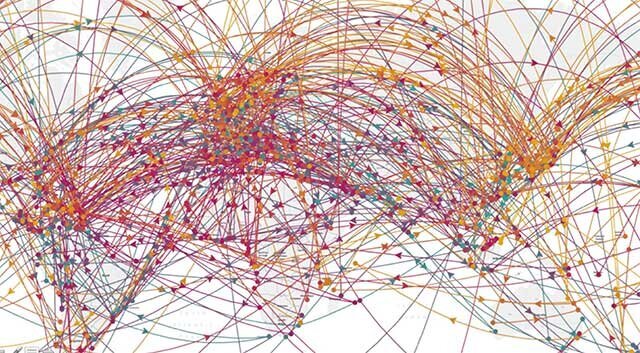

Supply Chain Mapping

Latest articles

Load More (0 / 0)

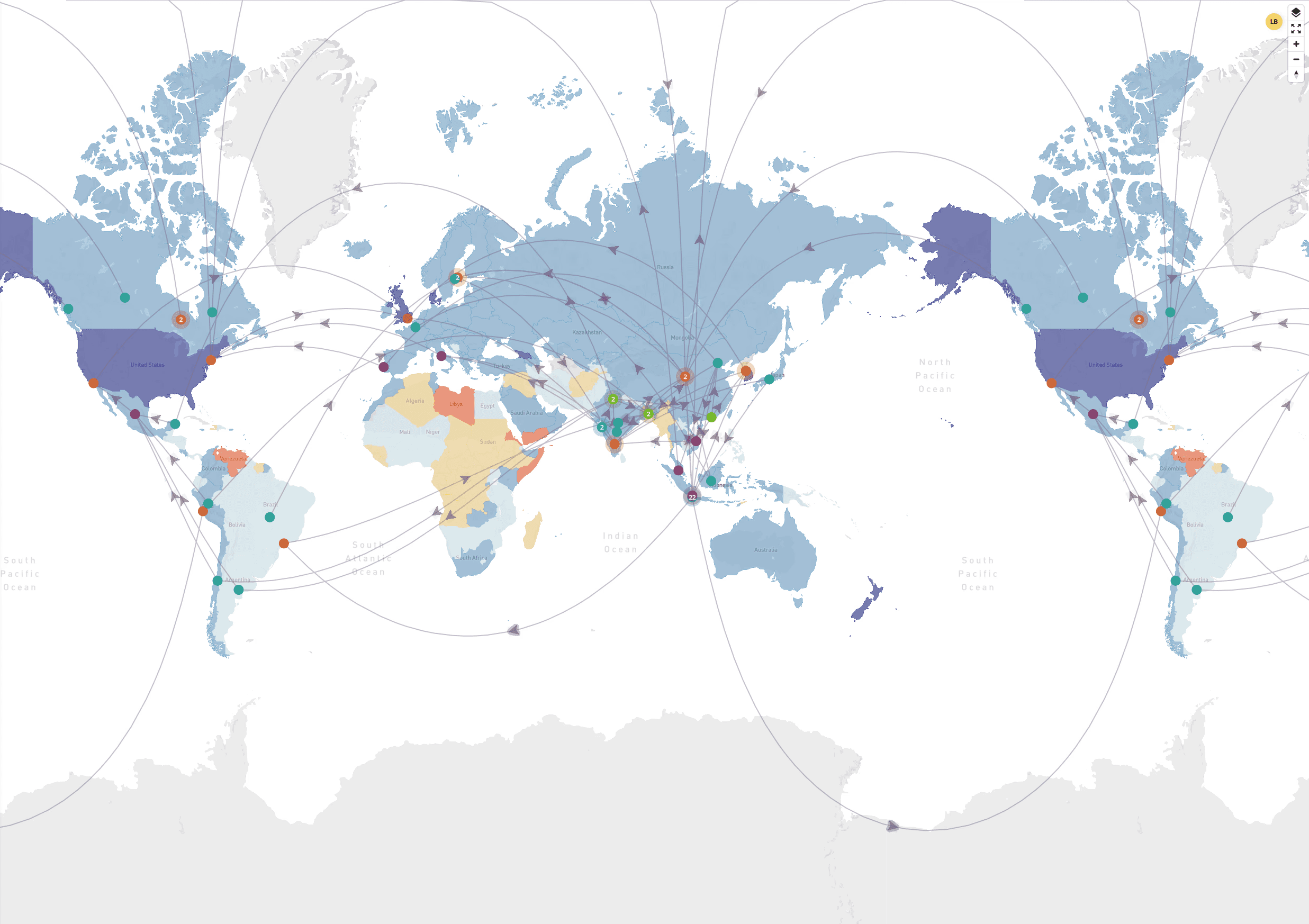

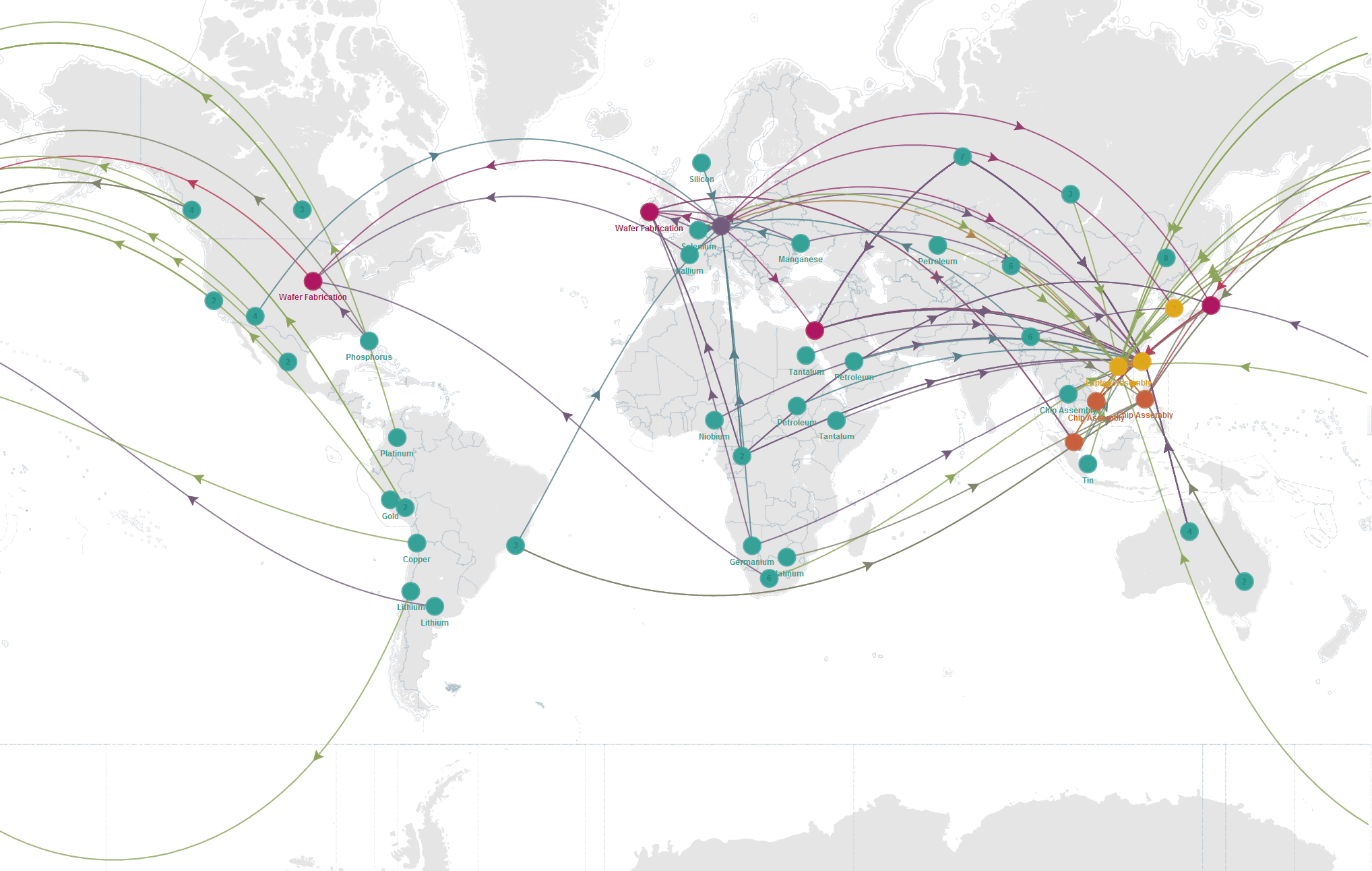

Let Us Help You Address Global Supply Chain Visibility Obligations With Confidence

Let Us Help You Address Global Supply Chain Visibility Obligations With Confidence