Dec 16, 2025

The ROI of Supply Chain Mapping: How One Auto Giant Mapped Its Way to Critical Materials

Securing the Future: How One Auto Giant Mapped Its Way to Critical Materials

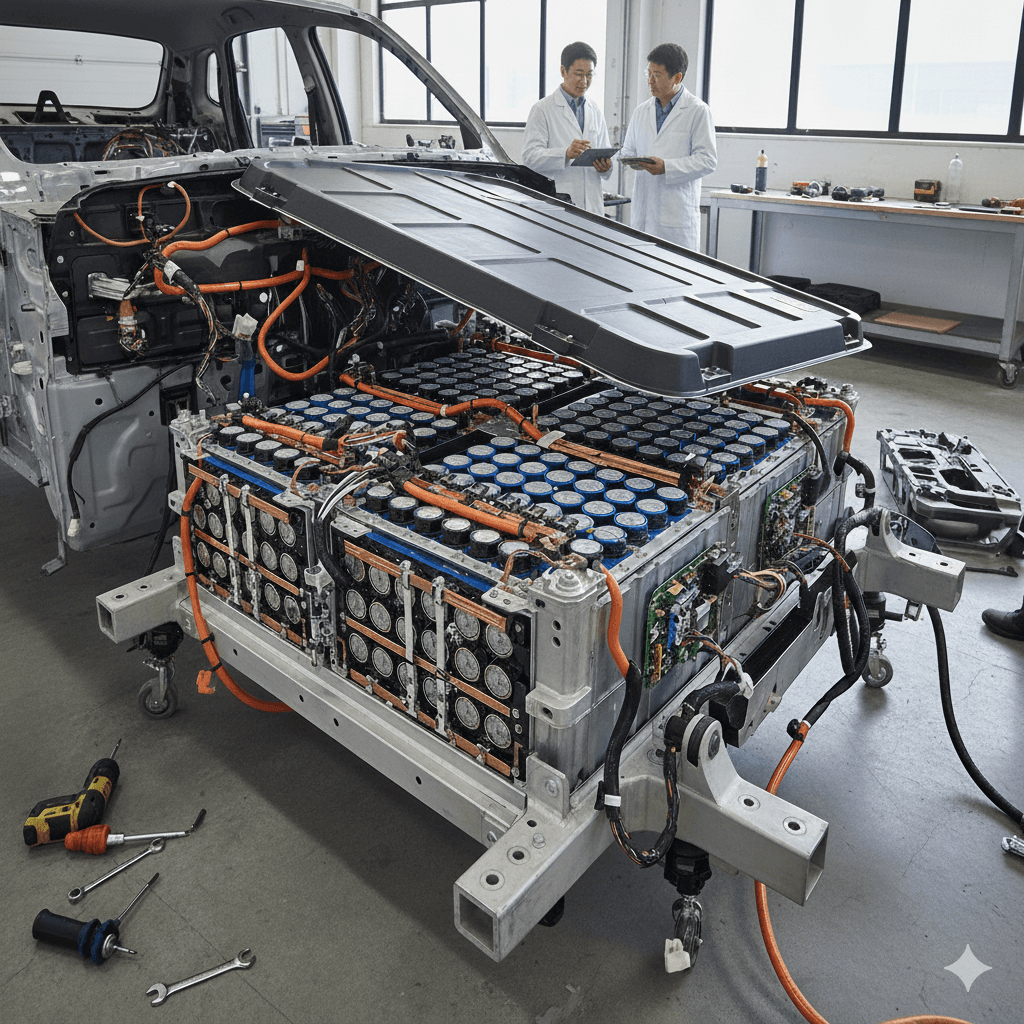

It is no secret that specialized manufacturing, especially in electronics and batteries, relies heavily on access to limited and rare earth materials. If you cannot source these strategic materials in a competitive and regulated environment, your success can be severely limited.

Think about what it takes to build an Electric Vehicle (EV) battery. The key to securing significant, long-term volumes of the necessary minerals is having complete visibility, not just of your direct supplier, but of the entire chain—down to the n-tier mines and the n-1 refining or smelting operations.

The Challenge of Visibility

A major global automotive Original Equipment Manufacturer (OEM), one of the top ten in the world, faced this precise challenge. They needed to supply their new EV battery factories, and that meant securing large volumes of critical minerals over the long term.

Their goal was not just supply; they also had to meet complex regulatory requirements and qualify for valuable incentives in the European Union (EU) and United States (US) markets. This often involves specific rules about where materials are sourced—the "friendly-country sourcing" requirements. Without knowing exactly where their minerals came from, meeting these standards would be impossible.

The Mapping Solution

To solve this, the OEM turned to supply chain mapping.

Within 60 days of launching a supply chain mapping portal, they were able to initiate a cascading process that located every metal mining operation and all the intermediaries, including the refining facilities, that fed into their supply chain.

Once the physical locations were identified, the procurement teams got to work. They collected crucial data on:

Capacity: Could these sites handle the volume needed for their new factories?

Compliance: Did they meet all the necessary regulatory and ethical standards?

This level of detail allowed them to ensure an uninterrupted supply and confirm they were meeting all the friendly-country sourcing requirements necessary to qualify for those key incentives.

The Impact: A Secure, Compliant Future

By strategically mapping their EV battery mineral supply chain, the automotive OEM achieved several significant outcomes:

They rapidly located mines and refineries, achieving full transparency within that 60-day window.

They were able to trace volumes to pinpoint the most strategic, high-capacity sites.

They confirmed sufficient reserves and capacity at these strategic n-tier suppliers.

They established long-term sourcing contracts directly with those n-tier suppliers of strategic metals. This moves beyond transactional buying and builds a resilient foundation for future production.

They developed comprehensive compliance programs for their strategic minerals supply chains across all operating countries, securing their eligibility for critical market incentives.

In essence, they transformed a complex, opaque sourcing challenge into a structured, compliant, and reliable system, paving the way for the successful rollout of their new EV factories.

Would you like to explore how supply chain mapping can provide similar visibility for a different type of raw material or component?