Nov 17, 2025

The ROI of Supply Chain Mapping: How a Luxury Giant Unlocked €85M+ in M&A Synergies

The ROI of Supply Chain Mapping: Case Study #1

Merged, Not Mapped: How a Luxury Giant Unlocked €85M+ in M&A Synergies

Mergers and acquisitions (M&A) are supposed to be exciting—but for many large conglomerates, the reality is a little messier. Instead of seamless synergy, you often end up with an expensive, tangled mess, especially in procurement.

We saw this happen with a top-10 global luxury conglomerate. They had expanded by acquiring multiple high-end brands, which seemed great on paper. However, beneath the same corporate umbrella, their own companies were actually competing against each other.

The Procurement Puzzle: Redundancy Runs Rampant

Imagine the confusion. This luxury conglomerate maintained redundant procurement teams—one for each brand. Each team was handling the scouting, onboarding, compliance, and management of its suppliers.

The big problem? Most of these suppliers served multiple brands within the conglomerate. This "siloed" approach led to massive inefficiencies:

Duplicate Efforts: Redundant databases and vendor management processes were everywhere.

Wasted Money: They had multiple contracts for similar products, often negotiated at different prices.

Compliance Overkill: There was needless duplicate auditing and compliance reporting across brands.

In short, they had an empire of luxury brands operating as rivals in their own back office.

The N-Tier Fix: Centralized Visibility

To solve this, the conglomerate implemented n-Tier supply chain mapping. N-Tier mapping is all about seeing the supply chain deep beneath Tier 1, all the way to the raw material and component origins. By leveraging this deep visibility, they were finally able to connect the dots across their entire corporate structure and achieve over €85 million in return on investment. Here's how they transformed their operations:

Balanced Control: They provided each subsidiary with a dedicated n-tier supplier database while centralizing visibility for the holding company. This meant local teams kept the data they needed, but corporate saw the big picture.

Smarter Spending: They could finally consolidate purchases of parts and services used by multiple subsidiaries, increasing their buying power.

Optimized Logistics: They were able to optimize the use of distribution sites, including warehouses and transshipment locations.

Streamlined Compliance: They eliminated redundant audits and compliance work, while simultaneously expanding the number of sites covered by their supply chain due diligence.

By mapping their n-tier suppliers, the luxury giant stopped competing with itself and turned redundant costs into strategic savings.

Interested to learn more about the ROI of Supply Chain Mapping? Get in touch with our experts.

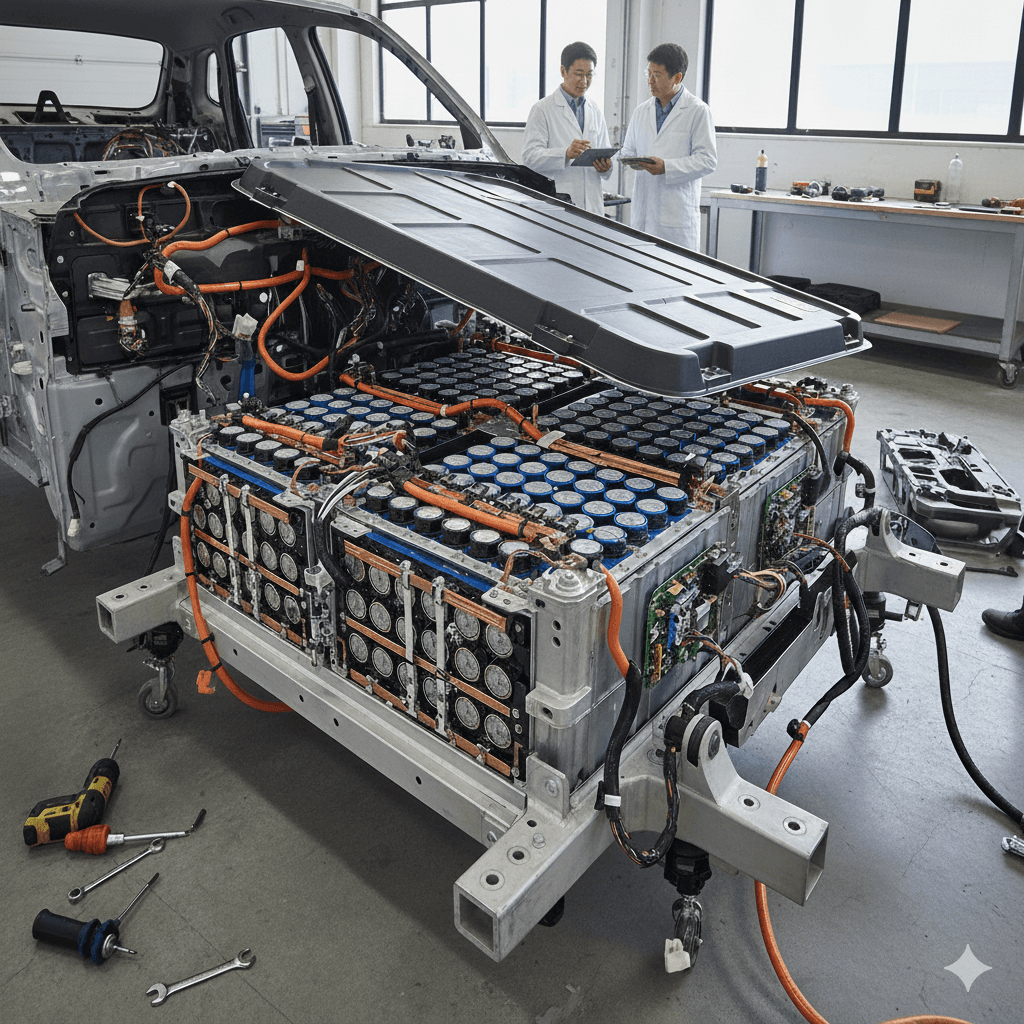

Would you like to hear about the next case study, which details how a global automotive manufacturer used mapping to secure over $100 million in strategic raw materials?